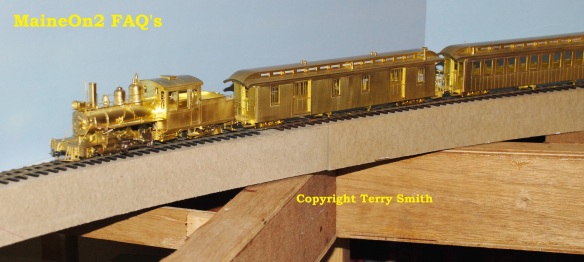

A Car Works B&SR #8 is staged on a piece of flex track curved to 18″ radius to show the coupler offsets.

Model locomotive minimum radius information

Tabulated locomotive data

|

Minimum Radius (inches) |

Locomotive Model |

Comments |

|

|

|

|

|

26 |

Putnam & Stowe SR#1 & #2 (0-4-4T) |

|

|

|

|

|

|

33 |

Custom Brass SR&RL #6 (0-4-4T) |

|

|

|

|

|

|

34 |

Custom Brass SR&RL #24 (2-6-2 + Tender) |

Peter Barney’s own model |

|

|

|

|

|

36 |

Custom Brass SR&RL #16, #18, #23 & #24 (2-6-2 + Tender) |

General |

|

|

|

|

|

36 |

The Car Works B&SR #7 (2-4-4T) |

Terry Smith’s own model (1) |

|

|

|

|

|

38 |

Custom Brass SR&RL #20, #21 & #22 (Eustis RR #7, #8 & #9) (0-4-4T) |

General |

|

|

|

|

|

42 |

The Car Works B&SR #7 & #8 Custom Brass SR&RL #10 (2-4-4T) |

General |

|

|

|

|

Note (1) OK on Precision Scale Flex track, marginal on hand-laid track. Rear truck modified to allow extra sideways movement.

The caveats

This information is given in good faith from published sources for un-altered models, and has stood the test of time in previous iterations of these FAQ’s.

It should also be noted that the brass loco’s used in On2 are hand assembled in small batches so that each model is an individual, and a particular example may not achieve the radius stated above. If this is critical, then appropriate tests should be performed to confirm satisfactory operation.

If hand-laid track is used then be aware of the inherent variations with this method/technique and how they can affect the minimum radius.

Note that other operational characteristics as well as aesthetics may set a higher limit than the numbers above. Rear coupler swing may be a particular issue with the larger Forneys such as B&SR #7  and their equivalents on the SR&RL.

Comments

The discussion of the required or recommended minimum radius for On2 has tended to polarize people and their contributions. Many folk appear not to recognise that the Forney locomotive design as used on the Maine Two Footers inherently has a large rear overhang (distance from the rear driving wheel to the rear coupler) and that in both the full-size and model form this overhang can limit how tightly the loco can curve and still remain coupled and on the rails. This rear overhang is particularly significant in the largest models such as B&SR #7 and close relatives.

A posting by Al Churella highlights this “…I told “ordinary” HO-diesel-era modelers that I model in On2, and they often say: “you must be able to get away with really tight trackwork, because it’s narrow gauge” and they are shocked when I tell them how much space that On2 eats up. I would hate to see an enthusiastic newcomer to the hobby lay 100 feet of On2 track with 24 inch radius curves and put down a dozen or so #4 turnouts (those are pretty common on many HO layouts, actually), then he wonders why his SR&RL #10 just won’t seem to handle the Rangeley Express very well. Better to be forewarned so that he can do a thorough reassessment of his layout space and make the kinds of changes that you suggest…”

Ed Kozlowsky based his home layout in 1895 and only used the much smaller Putnam & Stowe locomotives, and so could use tighter curves. Ed contributed a lot of useful data about using these engines, and this has been added to the model information here.

A final comment comes from former Two Foot modeller Trevor Marshall who wrote,;- “Every so often on the newsgroups, we’d get some guy who got a new Forney (probably the Bachmann On30 model) and wanted to know how TIGHT he could make his curves and turnouts. All sorts of people would wade in with opinions, but they fell into two camps:

– Those who had never built a Maine two-foot layout, or who had only spiked down some flex track to do experiments with their locomotives, would talk in terms of tightness. They’d pick curves like 30″r for On2, or 24″r for On30, and #6 turnouts.

– Those who HAD built a Maine two-foot layout – and especially those working in On2 – would talk in terms of broadness – they’d note that they’d used 42″r or 48″r, but really wish they’d used larger. Some used 60″r and felt that was barely adequate. All advocated #8 turnouts as a bare minimum.

The difference?; the group that had built layouts actually had experience with things like coupling/uncoupling, Forney rear tank swing, the LONG passenger cars (almost 50′) of the SR&RL and B&SR, and so on. Furthermore, they’d come to understand that the Maine Two Footers were built to 24″ gauge for purely economic reasons rather than geography (which played an important role on Colorado 3-foot lines). The Maine two-footers served sparsely-populated regions and towns or industries that could afford to pay for a 2′ RoW, but which could never have afforded the costs to build a standard gauge line. But the geography was not challenging – most of the mainlines followed riverbeds so broad curves were easy to lay and allowed for very fast trains. Books about the lines note that the SR&RL passenger trains routinely hit 60 mph in spots.”

Terry Smith writes;- Just in case you need some more persuasion, then take a look at the following pictures which show head and tail on views of the heading picture, in which a Car Works B&SR #8 is staged on a piece of On2 flex track curved to 18″ radius, and compare these with the last picture which shows the same engine plus Car Works combine #31 and coach #15/16 on a 48″ radius curve.

‘Nuff said?

Click here to view the related topic “Minimum radius, big Forneys and tight gauges, – some numbers!” on another page.

Click here to view the related topic “Coupler offsets and angular mis-alignments on curves” on another page.

Updated 25-May-2016

You must be logged in to post a comment.