In this post we show some of the commercially produced gauges available at various times.

Simpson roller track gauge.

Russ Simpson produced these gauges to suit variety of rail sizes (eg codes 55, 70, 83 & 100). They were first announced in July 1977 and were available direct and from suppliers such as Coronado Scale Models, Caboose Hobbies and BK Enterprises.

The section below was copied from the Simpson catalog;-

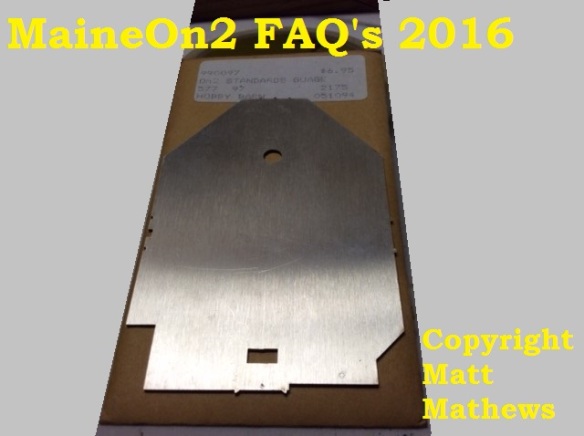

Portland Products NMRA style gauge.

Bob Werner produced this style gauge back in the mid 1990’s, and examples may turn up on eBay. One was offered as recently as mid-June 2016.

We know that SRE produced a cast brass three point gauge way back in 1970’s but we don’t have a picture or two – can you help?

On2 Yahoo group member John Rogers also produced a three point gauge in the late 2000’s to early 2010’s, but again we don’t have a picture or two – can you help?

Revised 02-07-2016 and 30-07-2017.

You must be logged in to post a comment.